BETONBLOCK®: NO CONCRETE TO WASTE

Have you ever wondered whether there is a way to squeeze more value out of your leftover concrete? A way to create a product so convenient, so useful that customers will flock to you? Our products are the solution you need!

What are the advantages of working with Betonblock® concrete molds?

● Save costs by reducing waste and disposal costs

● Best value for money, built to last

● Earn extra revenue by producing a resalable product

● One-stop shop and no additional shipping costs

● Sustainable concrete

What makes the Betonblock® system so special?

Large concrete blocks can be used to create structures that would be impossible with poured concrete. The system can best be compared to the common plastic bricks and work almost just as effortless. The blocks form a stable, moveable and highly scalable stacking system without requiring any mortar, making them ideal for temporary and/or permanent structures. A flexible response to your needs of tomorrow, whether or not they differ from those of today.

Easy production of functional concrete blocks

Betonblock®'s steel molds are precisely designed to enable contractors to produce highly functional concrete blocks with ease. The blocks fit firmly together thanks to the studs at the top and the recesses in the bottom of the blocks. This flexible construction method is an ideal way to easily extend or modify any structure at any time.

Concrete blocks are highly versatile and have numerous uses. They are ideal for partitions, retaining walls and trench silos, for instance in the recycling or agricultural sectors, but they also lend themselves perfectly for the construction of barns and buildings. Concrete blocks are also widely used for safety reasons, e.g. to block roads or as flood protection.

The Betonblock® product range

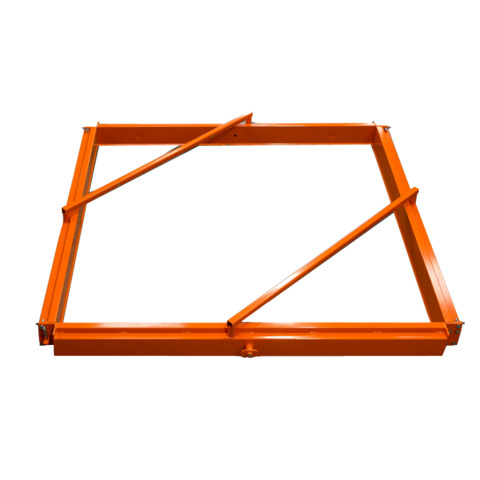

Betonblock®'s product range is as unique as it is comprehensive. Harness the multitude of different shapes and sizes to create highly aesthetic structures. Betonblock® carries special concrete block molds, retaining wall molds, concrete slab molds, barrier molds and tetrapod molds. And thanks to the dividers (sold separately), you only need one concrete block mold to produce different types of blocks. What’s more, using one or more straight dividers lets you create multiple smaller blocks in one go and in one mold. All molds are made of high-quality A572 structural steel and feature a powder-coated finish for enhanced durability.

To facilitate more efficient and cost-effective processes at construction sites, Betonblock® has developed a range of accessories to simplify block handling and transport. The block tipper and rotator can be used to put any block or slab in exactly the right position. Concrete block clamps make it easier to transport concrete blocks while concrete slabs can be moved with a special lifting and tilting mechanism or our new vacuum slab lifter.

Innovative system, satisfied customers

Since we introduced our first generation of steel molds 25 years ago, our innovative, easy-to-use design has made major waves. In fact, the Betonblock® system is the fastest-growing system in today's market. It can be said Betonblock® is the market leader in this field for a reason, with more than 9,500 customers in 90 countries worldwide. Our customers appreciate our high-quality products and fast delivery from our large stock. Powered by years of close cooperation with contractors and experience with concrete products, we can respond quickly to customers’ needs and wishes.

The power of Betonblock®

Betonblock® is all about getting its customers high-quality products quickly and efficiently. Products are delivered from stock and often shipped on the same day. Transparency is paramount, all prices are listed on our website and our team is happy to help you choose the most suitable product and matching accessories.

● Unique and comprehensive product range

● Best value for money

● Worldwide delivery from stock

● Cost-saving and user-friendly

● Built-to-last molds